Featured Products:

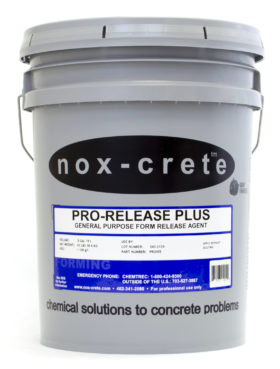

Product Description

Pro-Release Plus is an economical, water-based, general-purpose concrete form release agent that combines both chemically active and barrier-type components for improved performance with most concrete mix designs, including mix designs incorporating pozzolans such as fly ash or blast furnace slag.

Applications:

- Use on steel and fiberglass in precast applications, low-cost overlaid import plywood, curb and gutter forms, plastic and plywood faced handset forms.

- Use in commercial and residential concrete forming applications.

Advantages:

- Economical alternative to higher cost specialty type form release agents where cost per gallon considerations outweigh performance requirements

- Chemical and barrier components provide an improved release for most concrete mix designs, including mixes containing pozzolans such as fly ash or blast furnace slag

- Dries fast and is not slippery

- Resists removal by normal rain showers.

- Low odor, non-flammable, water-based formulation is safe to use and meets all federal and state VOC requirements.

- Green Engineered™ – better for health and the environment.

- Available with Winter Guard™ additive for cold weather application and storage. With Winter Guard™, Pro-Release Plus can be safely applied at temperatures above 25° F (-4° C) and can be stored at temperatures below 25° F (-4° C) without damaging the emulsion.

- Available as Pro-Release Plus Concentrate which can be easily diluted with water, kerosene, or fuel oil and provides excellent emulsion stability. When mixed with water, Pro-Release Plus Concentrate components stay mixed longer.

- Variable dilution rate allows the user the freedom to maximize Pro-Release Plus Concentrate performance depending on concrete mix design, stripping schedule and weather conditions by simply adjusting the dilution mix ratio.

- Pro-Release Plus Concentrate can also be used as a form maintenance coating to soften concrete buildup on forms by simply reducing the dilution ratio.

- Pro-Release Plus Concentrate will not freeze unless diluted with water.

Manufacturer Info

Nox-Crete™

In 1956, Carl Linn introduced the world’s first chemically active form release agent.

While working as a chemist for the United Petroleum Group in Omaha, Nebraska, Linn noticed concrete contractors were using the company’s oil and grease compounds to prevent fresh concrete from bonding to forms. Not only were the oil and grease compounds difficult to work with, but the resulting concrete was discolored and unpaintable. Plywood forms also suffered, failing after just a few pours. Concrete workers had struggled with these issues for years, but Linn had an idea.

He developed a chemically active release agent, Nox-Crete Form Coating, and a chemically active form maintenance product, Nox-Crete Deactivator. With Nox-Crete Form Coating, contractors produced concrete that looked better and wood forms that lasted longer. With Deactivator, the concrete buildup could be safely and easily removed from tools and equipment.

Today, Nox-Crete continues to manufacture chemical solutions to concrete problems.