Categories

Manufacturers

Search Products by Name:

Featured Products:

Browse by Category:

- Bonding Agents

- Bridge Deck

- Concrete Placing

- Curing and Sealing

- Decorative Concrete

- Diamond Blades

- Finishing Tools and Accessories

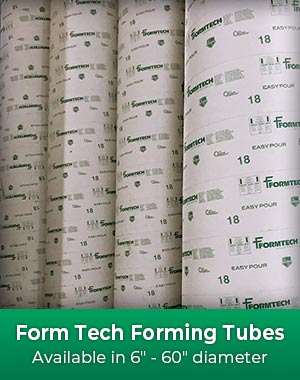

- Forming

- Grouts

- Insulation

- Joint Sealants and Expansion

- Lumber Products

- Mechanical Fasteners

- Miscellaneous

- Paving and Flatwork

- Reinforcing Products

- Repair Mortars

- Safety

- Trench Drain

- Vapor Barriers

- Waterproofing

- Waterstop

Home » All Products » Forming » Metal rib form » SureBuilt Metal Rib form

Product Description

The expanded metal sheets are easy to cut, lap, splice, bend and pierce, minimizing related forming costs. When concrete is placed, the ribs and mesh are embedded in the structure, providing a rough surface for subsequent concrete placement.

Features:

■ Reduces labor and material costs compared to traditional forming methods for wall joints and “buried” applications.

■ Saves cycle time because the sheet remains in place, only supports and bracing are removed, and form stripping is eliminated.

■ Allows concrete placement to be visually monitored, reducing the risk of voids and “honeycombing.”

■ Simplifies form joints and piercing so rebar operations can continue, or be revised, with minimal obstructions.

■ Provides a quick-to-install joint option in the event of a schedule change, ready-mix interruption or other unanticipated problems.

■ Utilizes the existing rebar in structures, like grade beams and pier caps, to eliminate placing and removing temporary supports.

■ Eliminates the cost associated with handling, setting, stripping and cleaning conventional formwork.

Manufacturer Info

SureBuilt

SureBuilt Concrete Forms & Accessories is a USA manufacturer of concrete construction products, including form ties, handset forms, bar support, Stud Rail, tilt-up hardware, precast hardware, and pipe braces. With locations in Chicago, Tampa, Houston, and Los Angeles, SureBuilt supplies independent dealers and their contractor customers throughout North America.

THE SUREBUILT™ LEGACY

Known as Universal Form Clamp, then as Universal Building Products, and most recently as SureBuilt, concrete forming products have been made at the Bellwood, IL location for almost 40 years. With more than 320,000 square feet under roof, there has been room to change and grow. These concrete forming products have been shipped to independent dealers and distributors, for resale and delivery to contractors, throughout North America, and at times internationally. There has always been a preference to work with local people who know local markets, not corporate entities. A history of being privately-owned established a culture of being responsive to customer needs, not shareholder demands. These needs include product design, application engineering, dealer financing, private labeling, marketing support, and reliable shipping. About 25 key individuals, each with 20+ years of experience and a personal association with the owner, manage daily operations, and demonstrate this commitment to customer responsiveness. And it doesn’t stop there. We always seem to be installing new equipment and updating existing work cells, making the ongoing “Made In U.S.A.” mission even more efficient, effective, and competitive. Find out for yourself why we’re manufacturing and shipping more concrete construction products than ever before.

Related Products:

| Image | Name |

|---|---|

| Double Flared Coil Loop Insert SB Precast, double flared coil loop insert. |

| Stud Rail SB Stud Rail is a double-headed stud anchor (DSA) reinforcement system, typically used for concrete deck-to-column connections. The system is designed to transfer the load further into the concrete deck, create a larger shear area around the column, and resist punching shear forces. |

| SB TieLock™ Forming System The TieLock self-centering tie and bracket, with 3/4” plywood as 3/4” plywood as the form face and 2x4 lumber as the waler, creates an economical concrete forming system. |