Featured Products:

Product Description

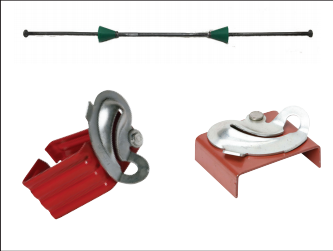

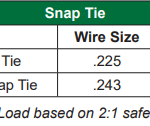

Job-built forming with 3/4” plywood, 2×4 lumber, Snap Ties and Jahn-style Brackets are popular on many construction sites. Though only a few components are required, time and labor are necessary to plan, mark, cut, and drill the plywood.

Short-end (SE) Snap Ties are available for conditions with single walers on both sides. Long-end (LE) Snap Ties are available for conditions with waler/strongbacks on both sides. Odd-end (OE) Snap Ties are available for conditions with a single waler on one side and waler/strongback on the other.

Short-end (SE) Snap Ties measure 4-3/4” at each end, plus the wall thickness. Long-end (LE) Snap Ties measure 8-1/4” at each end, plus the wall thickness. Odd-end (OE) Snap Ties measure 4-3/4” at one end and 8-1/4” at the other end, plus the wall thickness.

Every Snap Tie includes two 1” plastic cones. The plastic cones set the wall dimension and cover the plywood hole. After the plywood is stripped, the plastic cone and exposed tie end are removed with a twist.

Manufacturer Info

SureBuilt

SureBuilt Concrete Forms & Accessories is a USA manufacturer of concrete construction products, including form ties, handset forms, bar support, Stud Rail, tilt-up hardware, precast hardware, and pipe braces. With locations in Chicago, Tampa, Houston, and Los Angeles, SureBuilt supplies independent dealers and their contractor customers throughout North America.

THE SUREBUILT™ LEGACY

Known as Universal Form Clamp, then as Universal Building Products, and most recently as SureBuilt, concrete forming products have been made at the Bellwood, IL location for almost 40 years. With more than 320,000 square feet under roof, there has been room to change and grow. These concrete forming products have been shipped to independent dealers and distributors, for resale and delivery to contractors, throughout North America, and at times internationally. There has always been a preference to work with local people who know local markets, not corporate entities. A history of being privately-owned established a culture of being responsive to customer needs, not shareholder demands. These needs include product design, application engineering, dealer financing, private labeling, marketing support, and reliable shipping. About 25 key individuals, each with 20+ years of experience and a personal association with the owner, manage daily operations, and demonstrate this commitment to customer responsiveness. And it doesn’t stop there. We always seem to be installing new equipment and updating existing work cells, making the ongoing “Made In U.S.A.” mission even more efficient, effective, and competitive. Find out for yourself why we’re manufacturing and shipping more concrete construction products than ever before.